RUGGED EQUIPMENT FOR

HAZARDOUS AREAS

Protecting your equipment in demanding temperature, vibration or dust environments, without sacrificing performance.

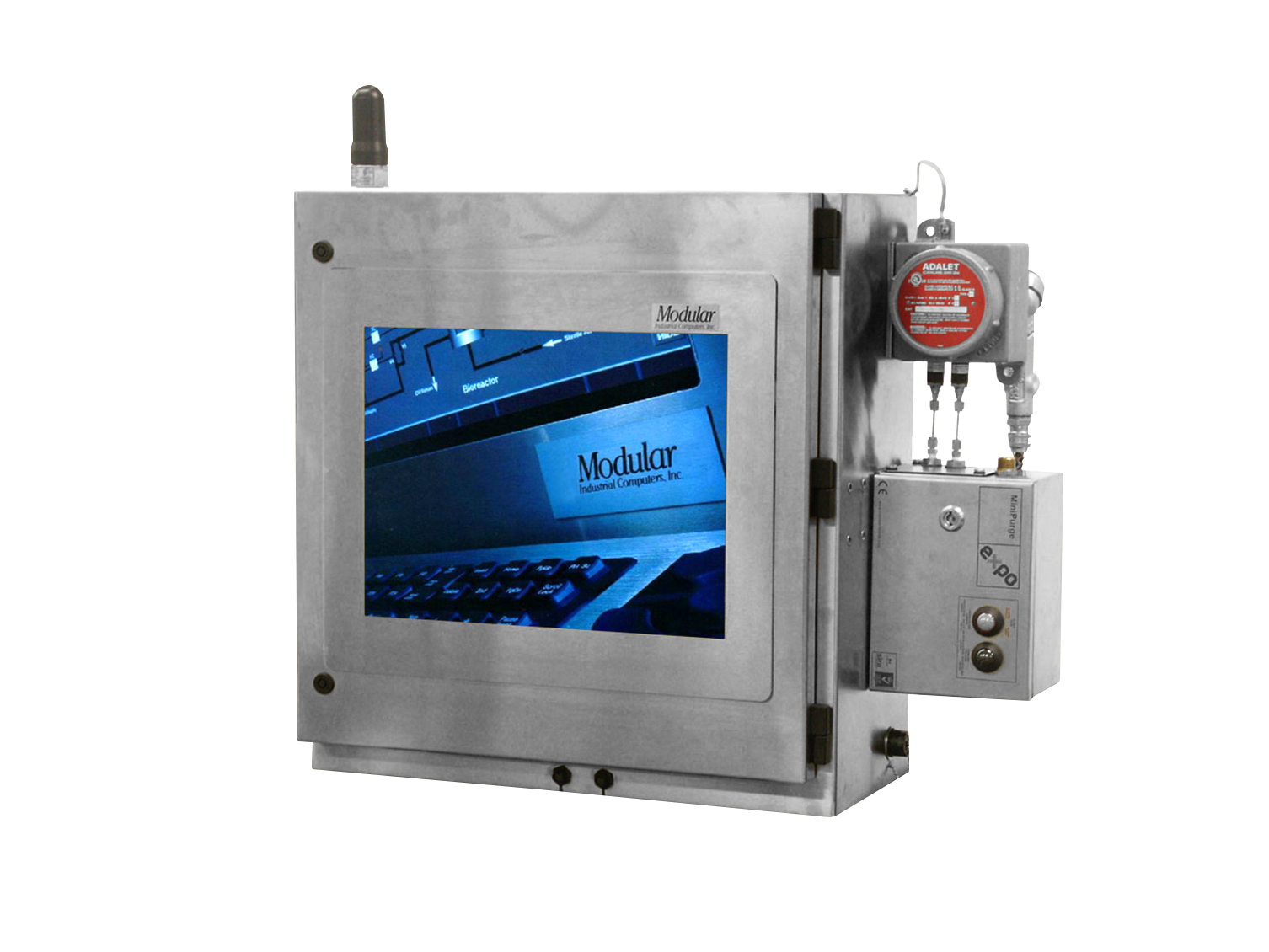

Hazardous environments demand equipment that can be serviced quickly, withstand extreme temperatures, and keep operations moving without costly delays. Modular’s HMI platforms - including the FS PowerBox, WorkStations and Large Screen Enclosures - are built with easy field serviceability at the core. This means operators can swap components, access internal hardware and deploy new computers or Thin Clients in minutes, not hours.

CHALLENGES WE SOLVE

Easily

Field-Serviceable

Reduce Downtime &

Maintenance Costs

Flexible

Customization Options

OUR SOLUTIONS

Our systems are built to outperform traditional enclosure options in the demanding environments of food and beverage production. Every unit is manufactured with long-term durability, precise fit and finish, and ergonomic design that makes daily operation smoother for production teams. With reliable protection for modern industrial computing hardware and a track record of proven performance, Modular delivers a solution that simplifies deployment and strengthens operational reliability across the entire facility.

What can I expect from Modular Industrial Computers?

Shorter Average Lead Times

Industry-Leading Warranty & Support

Lower Overall Cost

Higher Build Quality

Customizable Configurations

BUILT FOR COMPLIANCE

Certified to NEMA 4 / 4X and IP69, our solutions are built to outperform washdown and sanitation demands in food, beverage, meat, and dairy processing environments. With hygienic surfaces, sealed industrial enclosures, and proven protection against high-pressure spray, chemical exposure, and daily sanitation cycles, they ensure continuous compliance on every production line.

CLASS I, DIV 2

CLASS I, DIV1

SPECIALITY & CUSTOM BUILDS

No two production environments are alike - even on the same plant floor - which is why we design custom industrial enclosures and workstation solutions purpose-built for your application. Whether you’re dealing with extreme temperatures, corrosive washdown zones, food-processing hygiene requirements, or space-limited installations, our NEMA 4 / NEMA 4X enclosures, IP69-ready industrial display sytems and rugged PC WorkStations are designed to fit seamlessly into any unique setup.

If your facility has a challenge, we deliver a fully customized solution built for real industrial protection.

Food and Beverage processors across the U.S. rely on Modular’s hardware to keep their production lines running in harsh washdown environments. Our systems are in daily use at facilities ranging from large national producers to specialized regional manufacturers.

TRUSTED BY THE INDUSTRY

START YOUR SOLUTION

Modular delivers hardware that lasts longer, installs easier, and performs better in the toughest industrial environments - all with competitive pricing, fast lead times, and a superior warranty. When reliability, flexibility, and long-term value matter, Modular is the partner you can depend on.

Feel free to contact us by submitting a contact form, below, or by calling or emailing us directly. We look forward to assisting you with your next Plant Floor Certified Solution.

Monday - Friday

8:00am - 5:00pm

sales@modularpfc.com

insidesales@modularpfc.com

6634 Lee Highway

Chattanooga, TN 37421